· HOME > HSWG Heat Dry System > HSWG Heat Dry

HSWG Heat Dry System

HSWG Heat Dry

1) Principle

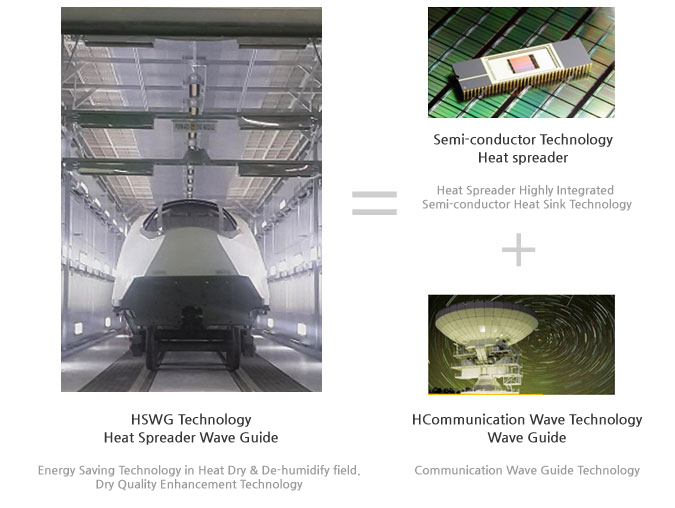

This suggested facility, HSWG Heat Dry Technology is an energy saving technology converging the highly integrated semi-conductor Heat Spreader and (HSWG: Heat Spreader/Wave Guide)

Heat Spreader Technology named after the heat sink bonded at the back side of a highly integrated semi-conductor that composed of powder with 99.99% purity in far infrared ceramic, and Wave Guide technology is an optic communication guide device. HSWG technology, converging two technologies having been developed and used for past 100 years has been developed about 15 years ago as an energy saving technology. (NEP: Notifiction of the Korean Agency for Technology and Standards under the Ministry of Trade, Industry and Energy).

This energy saving technology can be applied to not only a new facility but also existing facilities now in use. It would bring an excellent outcome with the same amount of energy saving and the same quality enhancement as that from a new facility if applying it in remodeling of an existing facility.

Details of data are listed about dry quality enhancement and energy saving efficiency at the data column for those delivered facilities now in operation.

2) Structure and Characteristics

① Drying booth with Wave Guide material

The drying chamber of this suggested facility constructed with the Wave Guide material allows electro-magnetic wave to hover only in a booth and to be absorbed into the object to be dried. It enables the maximum energy saving. And the lower temperature in the chamber than that in the object materializes the best quality in the painted dry quality (painted film) without a pin-hole. When drying agriculture and fishery products, it promises undamaged dry quality same as that from natural dry. For example, those sun-dried pepper and dried fish can be mass produced in a hygienic condition.

Drying booth with HSWG Materials

Electric energy->Heat energy->Electro-magnetic wave->Guides the electro-magnetic wave to painted area on the object to be dried -> The electro-magnetic wave penetrates into the painted area and generates heat so that higher temperature in the painted area than that of the air in the chamber brings the best painted quality.

① Converts electric energy to heat energy in the heat spreader module at the painted area and converts it to electro-magnetic wave energy beneficial to human.

② The wave guide at the area guides and irradiates electro-magnetic wave energy only to the painted area of the object for heat treated dry.

Convert electric energy to electro-magnetic wave beneficial to human (far infrared)

Device enables to irradiate electro-magnetic wave (far infrared) energy to the object evenly.

Can be constructed by bonding it to the existing booth.

Wave Guide Wall (roll screen type)

② Heat Spreader module and Electro-magnetic wave Damper

Heat Spreader module, a far infrared producing device in a longitudinal shape whose interior is built with wave guide material, is designed to irradiate electro-magnetic wave energy being converted from heat energy.

Heat Spreader module has higher conversion rate to electro-magnetic wave and 30 times longer irradiation distance than an existing far infrared heater has.

Electro-magnetic wave pouring out from the longitudinal Heat Spreader fills in the drying chamber and provides heat dry by penetrating directly only into the object to be dried.

Since the surrounding temperature around an aircraft is lower than that of the aircraft, it does not allow any pin hole on the dried paint film and shows higher efficiency in energy saving.

In addition, the electro-magnetic wave damper enhances energy saving efficiency and provides a cool job environment by controlling heat.

3) Comparison with existing facility

HSWG Heat Dry facility encompasses all the strong points of the heat blowing dry facility, the electro-magnetic dry facility, and the recent vacuum dry facility as shown on the table of the comparision with existing facilities below.

<Table of the comparision with existing facilities>

Product

Item

|

heat blowing drier (Small ~large drying facility) |

electro-magnetic drier (Small & medium size) |

recent vacuum drier (small size) |

|---|---|---|---|

| Main Usage | -Drying painted surface -Drying agriculture & fisher products -Drying fabric & wood products -Large drying facility available |

- Drying food & food material /cooking/ - Drying surface finish as on semi-conductor, display, PCB, etc. - Drying pharmaceutical products. |

Special drying for naturally dried quality including agriculture & fisher products. |

| Principle of drying and characteristics (Strong points) |

Principle to evaporate moisture or solution in an object to be dried through convection of heat blow (dry/moisture air) from burner by a fan. Available in a large facility, however, dried quality is more or less in average. (The weakest point is pin hole effect resulted from the object surface dries first due to higher temperature of the dry chamber than that of the object) |

· Electro-magnetic wave heats the object.Temperature in the dry chamber should be lower than that of the object in theory, but higher in practice, which brings similar result to the heat blow dry with the same weak points as the heat blow dry has. | · Dries the object at low temperature by lowering the boiling point of moisture or solution in the object with vacuum (lowered pressure) in the dry chamber. The dried quality is similar to that of natural dry. Same effect as on the sun dried pepper. |

| Structure & Characteristics (Strong points & weak points) |

· Continuous running of burner, heat blow producing device, and fan/vent is required and increased manufacturing cost for insulation between inner wall and outer wall in the dry chamber. | · Heating the dry chamber air by the heater of electro-magnetic wave brings same result as the heat blow dry does. Same weak points as the heat blow dry. | · A far infrared heating device in the dry chamber is excellent in energy saving, however facility cost is expensive (initial). Not available for a large facility. |