· HOME > HSWG Heat Dry System > HS Module

HSWG Heat Dry System

HS Module

HS Module (HS : Heat Spreader Module)

-

240m/m 1220m/m 225m/m (W) (L) (H) Width Length Height Electricity 3kW/EA

Durability: Almost Permanent

| New Technology Product(NEP) | Existing Product |

|---|---|

|

|

| Electricity entered in part ① produces heat energy through electricity heat-generating material, This heat energy converts to electro-magnetic energy at part ② electromagnetic wave changing material. Part③ is a housing designed to prevent convection heat loss for higher electromagnetic wave conversion efficiency. Part ④ is a radiation wave damper to make shop atmosphere cool and to increase energy saving efficiency by regulating heat. | Designed to heat air by burning fuel oil. |

|

Difference · No noise, no vibration when drying · Even an unskilled worker can accomplish without pin hole (inner side ---> outer side) · Almost no dust produced (pleasant environment) - Lower possibility for dust to settle on the painted surface when painting · Saving electric energy (no need to install fan) - Registration for Certified Emission Reduction in progress after application · Extended durability (two ~ three times) of consumables like a roof filter. · Increased safety thanks to absence of fuel tank in a factory. |

Difference ·Noise and vibration when drying · If not a skilled worker, higher possibility of pin hole when painting (outer side ---> inner side) · Likely to produced dust and bad shop atmosphere caused by hot air - higher possibility for dust to settle on the painted surface when painting · Big amount of energy consumption (fuel + electricity) - Tax burden for the certified Emission Reduction · Frequent exchanges of consumables including a roof filter. · Risk of safety accident due to presence of fuel tank. |

Comparison with existing driers (near, far infrared heater)

Product

Item

|

HSWG | Halogen Heater | Far Infrared Heater |

|---|---|---|---|

| Product Picture |  |

|

|

| Infrared Radiation Cross section (= Efficiency) | 100Pi | 10~12Pi | 11.3Pi |

| Irradiation Heating Range | All direction irradiation heating | Heating only irradiated area by mirror plate | Heating only irradiated area by mirror plate |

| Irradiation Distance | 20M Unified heating on large area (=heat treatment for a large object) |

2M Intensive heating on small area (= for a conveyer type heat dry) |

0.8M Unified heating on small area (= for a conveyer type heat dry) |

| Durability | 8~10years | 1~2years | 2~3years |

-

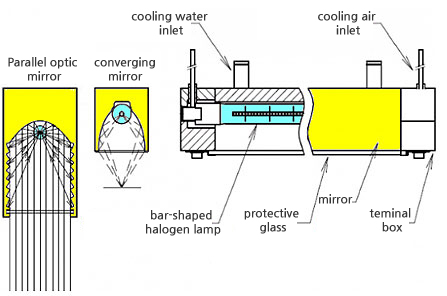

Reference figure A near infrared (halogen) heater using a mirror (reflecting device) parallel optic irradiation method,

requires a cooling unit to avoid deformation shortening its durability caused by uneven rise of temperature to 1000 ~ 1200°C between

the irradiated area and non-irradiated area of the object to be dried.